WE SPECIALISE IN THE PRODUCTION OF DRILLING TOOLS AND ACCESSORIES FOR THE FERROUS METALLURGY INDUSTRY.

Since 1969, GRABER Srl has been providing its customers with ferrous metallurgy accessories in many countries around the world.

Being ahead of the curve regarding the continuous evolution in the market, GRABER Srl focuses on the flexibility and dynamism of its service, investing heavily in innovative technologies and highly qualified personnel.

The special manufacturing process which creates tubes from solid billets permits GRABER Srl to meet even the most demanding orders on a “just-in-time” basis while still retaining high-quality standards.

Our technical department is available to customers to develop optimal solutions, even in the event that custom sizes and dimensions are required, and provides solutions with very short lead times.

Our history

GRA.BER srl was established in 1968 by the current chairman Ferruccio Grandi, his brother Franco and father Romano under the title of Bulloneria F.lli Grandi snc.

GRA.BER srl was established in 1968 by the current chairman Ferruccio Grandi, his brother Franco and father Romano under the title of Bulloneria F.lli Grandi snc.

The new family-run business, located in Crusinallo di Omegna, initially dealt with mechanical machining for third parties and general refining processes.

Shortly thereafter, the number of orders increased and the available space was no longer sufficient, so the decision was taken to build a larger, more functional building. The factory in Via XX Settembre, with its extensions and modifications, is still effective and in operation today.

Improved logistics and more space permitted the hot forming of special hardware, which was added to the general mechanical machining of the early 1970s. The company continued to devote almost all of its time to this area for a decade. At the end of the 1970s, the experience gained in the ferrous metallurgy industry permitted a new challenge to be taken up, that of producing drilling rigs for blast furnaces.

The turning point in production that lead to the one currently in place, and the consequent abandonment of hot forming, took place due to the premature death of Franco, one of the Grandi brothers. The current chairman, Ferruccio, made the decision to abandon the more commercial product linked to forming in favour of a decidedly niche product – drilling rigs and ferrous metallurgy accessories.

It was in 1982 that GRA.BER srl was established which, over the years, developed its expertise in the field of deep drilling using it to produce tubes with specifications that were second to none.

These would be used for the subsequent production of drilling rigs for the blast furnace casting nozzles, adding enormous value to what had been achieved thus far.

It was in 1982 that GRA.BER srl was established which, over the years, developed its expertise in the field of deep drilling using it to produce tubes with specifications that were second to none.

These would be used for the subsequent production of drilling rigs for the blast furnace casting nozzles, adding enormous value to what had been achieved thus far.

The uniqueness of the product and a twenty-year partnership with its most established customers allow GRA.BER srl to continue to hold the position of global leader in terms of production technology and the quality of its products.

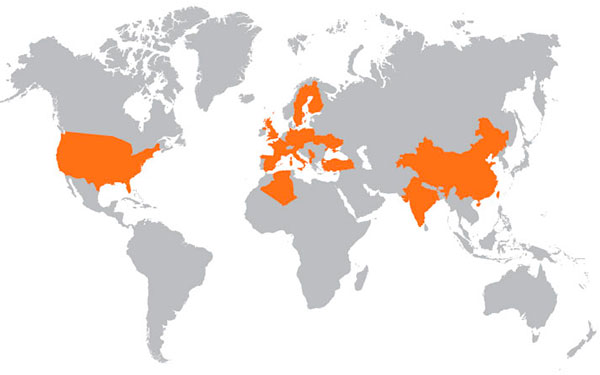

Today the company is a supplier to the world’s leading ferrous metallurgy groups and is recognised as a reliable, progressive and proactive partner.

The production of drilling rigs is complemented by a large number of types of accessories for the ferrous metallurgy industry in general, ranging from injection lances to check valves, from shank couplings to many other parts used daily in steel mills all over the world.

GRABER srl operates solely within the borders of Italy. The complete cycle, from design to shipping, takes place in the 2 production units in Gravellona Toce.

Timeline

-

1968

Ferruccio Grandi with brother Franco and father Romano establishes Bulloneria F.lli Grandi snc

-

1973

Beginning of hot forming of special hardware

-

1978

The experience gained in the ferrous metallurgy sector permits drillbars for blast furnaces to begin.

-

1982

GRA.BER srl established, a company specialising in the deep drilling sector.

-

2009

Quality: ISO 9001/2008 obtained

-

2012

Environment: Construction of 48.1 kW photovoltaic system

Follow GRABER on linkedin

Our LinkedIn page includes weekly updates and news about the company and the world of ferrous metallurgy

Follow us on LinkedinWhy choose us

GRABER is not only a supplier but also reliable partner in the development of new tailor-made solutions.

Read moreWhat you get

High-quality products, designed down to the smallest detail, created with respect for the environment and high-quality standards

Contact us now